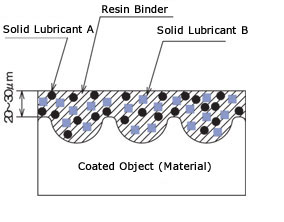

Embodiment of solid lubricant film formation

Here, the process and characteristics of the performance coating film that is the embodiment of dry-type lubrication film, wherein solid lubricants such as molybdenum disulfide, graphite, and PTFE are dispersed within organic and inorganic special binder. (excerpt from Nihon Metal Technical Co., Ltd.)

【Feature】

- Can be used as perpetual lubricant.

- Exhibits long-term effects on areas that cannot be refueled with oil, grease, etc., against sliding surface.

- Initial conformability effect for lubrication under high load.

- Maintenance-free is realized by forming favorable sliding surface early on initial conformability region.

- Treatment is possible for not only metal, but also for rubber and plastic.

- Able to give slidability and stability in wide region from low temperature region (-100℃) to super high temperature (800℃).

- In addition to low friction and anti-wear lubrication, anti-corrosiveness can be given.

- 5-100μm of coating film thickness can be achieved.

- Diverse treatment method. We provide an efficient and low cost coating film at high quality for single product to mass production products, using a treatment system such as spray, dipping, and dispenser.

- Thermal characteristics such as heat dispersion and thermal insulation as well as electrical characteristics such as conduction and electrical insulation can also be added.

【A Functional coating film-forming image view 】

Performance coating (dry film) process

Degreasing cleaning

Impurities stuck to the component surface from machining and rustproofing are removed to enhance adhesiveness of dry film coating. Polar solvent, nonpolar solvent, and aqueous solvents are primarily used as cleaning solvent.

Preprocessing

Preprocessing is performed for the purpose of expanding adhesion area (surface roughness), removing rust/crack, and improving wettability of the dry film coating on the component surface.

Phosphating, shot blasting, corona discharge treatment, alumite treatment, etc.

Secondary cleaning

A preprocessed product usually has shot blast particles stuck to its surface, so another cleaning is preformed to completely clean the surface.

If rubbish remains during this process, it can get in to the coating surface, which would ruin the lubrication effect and affect product precision after assembly, so the cleaning is an important task.

Preheating

The product which has been completely cleaned on the surface is slightly heated so that the coating does not drip off of the surface.

By doing so, coating dries faster, preventing it from dripping off.

Painting

Coating of solid lubricant is a process of spray coating the coating material in the following sequential order: “hand blowing by coating gun,” “automatic coating by automatic coating gun,” “automatic coating line, which performs cleaning to firing unmanned.”

Other coating methods include “tumbling,” “dipping,” “printing,” “dispenser,” etc.

Drying and thermal curing

Coating of solid lubricant is a process of spray coating the coating material in the following sequential order: “hand blowing by coating gun,” “automatic coating by automatic coating gun,” “automatic coating line, which performs cleaning to firing unmanned.

Product inspection

The product taken out of the furnace is inspected for film pressure and coating surface condition.