Intended use of Rail Sweeper

We have three different types of rail sweepers: Standard Type, With a ground belt type, and Felt Type.

The Standard Type sweeper featuring a diagonally mounted scraper which is to prevent dust from escaping through the brush bristles is for removing foreign materials such as dust and oxide film on the rail surface.

The Rail Sweeper with a ground belt discharges electrostatic and electric leakage charged mainly on the crane body to the rail (ground) through the brush grounding belt.

The Felt Type sweeper, equipped with felt instead of a stainless brush, wipes off oil and moisture on the rail surface to prevent slipping of the wheels.

In 1982, Tokyo Metropolitan Industrial Technology Research Institute (former Tokyo Metropolitan Industrial Technic Institute) verified the grounding performance of the With a ground belt type sweeper through a current waveform test installing the sweeper on an actual 5t overhead traveling crane.

The sweeper has been filling the role of antistatic measure for cranes which was used in various industries and businesses since then.

Under the supervision of Professor Kazuo Yamamoto from Department of Electrical and Electronic Engineering, Faculty of Engineering, Chubu University, we conducted an artificial-lightning strike test to measure the capability of the antistatic rail sweeper (With a grounding belt) to countermeasure against lightning strike, consulted by a customer about the application possibility of the antistatic sweeper. At the same time, a low voltage test was also carried out to reverify and update the result of the current waveform test in 1982.

Ⅰ.Anti-lighting test for Rail Sweeper (with a grounding belt)

Test venue

High-Voltage Laboratory, Department of Electrical and Electronic Engineering, Faculty of Engineering, Chubu University

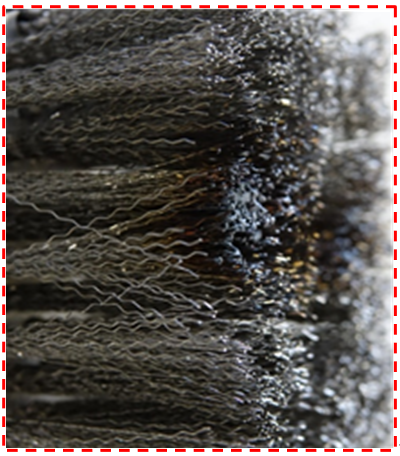

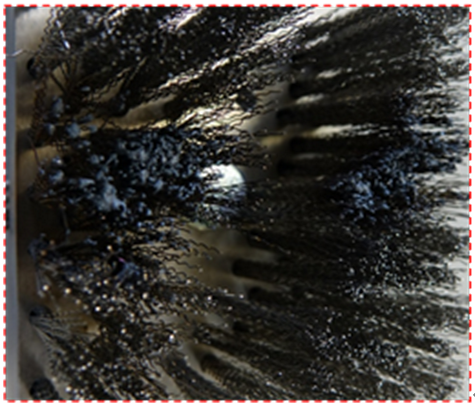

Test object

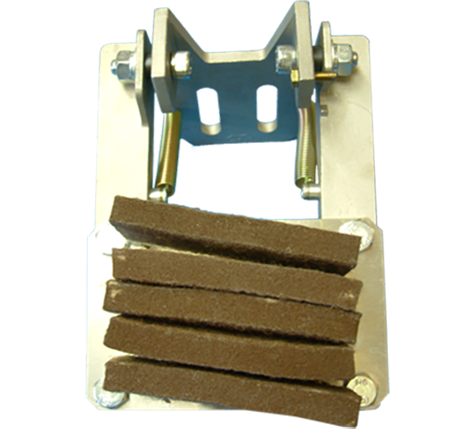

Product name: Rai Sweeper small (With grounding belt)

Purpose

Lightning is the occurrence of a natural electric discharge with a high current and voltage. The damage of machinery caused by lightning increases in proportion to electric charge. (C: Coulomb). The test, with an altered amount of electric charge, was to assess the damage of brush ends and the electrical conductivity to the ground when the rail sweeper (With a ground belt) brush is charged to the rail with a long stroke waveform and high current.

Test method

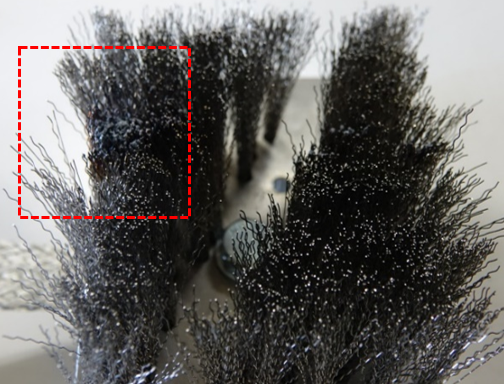

Using a long stroke waveform and high current generator, the charging filled with a long stroke waveform and high current was conducted to the rail sweeper (With a ground belt). Then the state of the discharge from the brush to the rail, the waveform thereof and, the damage of the brush ends was measured.

The test was conducted for one charge at a time resulting four times in total, between 1kV (6kA) and 4kV (24kA).

Test equipment, jigs, etc.

Test result

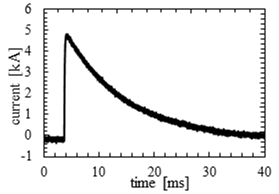

1.1 kV charge: Peak value 4.8kA, charge amount 46.9 C (Coulomb)

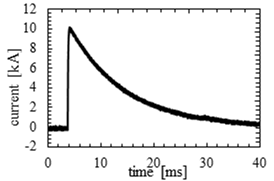

2.2 kV charge: Peak value 10.2kA, charge amount 106.0 C (Coulomb)

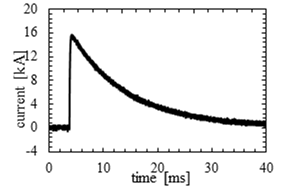

3.3 kV charge: Peak value 15.7kA, charge amount 169.8 C (Coulomb)

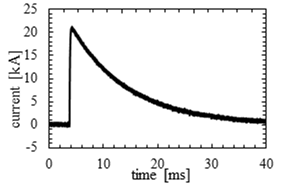

4.kV charge: Peak value 21.2kA, charge amount 224.4 C (Coulomb)

Discussion

(Quoted from the report of Professor Kazuo Yamamoto of Electrical and Electronic Engineering, Faculty of Engineering, Chubu University.

With this test, we energized long stroke waveform and high-current electricity to Rail Sweeper (with grounding belt) using long stroke waveform and high-current generator. As the result shows, current was successfully conducted from the brush to the ground. Thus, it is safe to say that lightning current can be safely transferred to the ground even when a lightning strikes a crane installed with the rail sweeper.

As the chart in the reference (1) shows, “Electric charge of the cumulative frequency distribution of the winter lightning on the coast of the Japan Sea”, winter lightning is more dangerous than summer lightning due to its large amounts of electric charge and tendency to strike on tall structures. This experiment was conducted to verify the fact that the brush can withstand lightning during the winter season which is severer than the summer season. Lighting with electric charge of more than 224.4 C, which is the largest charge amount in this test, accounts for 5 % approximately (1). In other words, the test proves that the brush can withstand the remaining 95% of winter lightning. As a side note, considering the state of the brush after the test, we can safely say that it can discharge an even larger amount of lightning charge to the ground without any problem.

Reference

(1) New Energy and Industrial Technology Development Organization: “Research and Development of Next-Generation Wind Power Generation Technology for Technology Corresponding to Natural Environment etc. for Measures of lightning protection”, p. 34

The video of electric discharge

46.9C

106.0C

169.8C

224.4C

Ⅱ.Low Voltage Conduction Test of Rail Sweeper (with a grounding belt)

Test venue

Kazuo Yamamoto Lab (branch office), Department of Electrical and Electronic Engineering, Faculty of Engineering, Chubu University

Test object

Product name: Rai Sweeper small (With grounding belt)

Purpose

In 1982, Tokyo Metropolitan Industrial Technic Institute verified the grounding performance of the sweeper with a grounding belt through a test on the current waveform installing an actual 5t overhead traveling crane on the sweeper. The purpose of the test was to prove if the Rail Sweeper (with a grounding belt) can perform grounding from high to low voltage from the brush through to rail, by constructing special conditions of low voltage electrical performance in the laboratory.

Test method

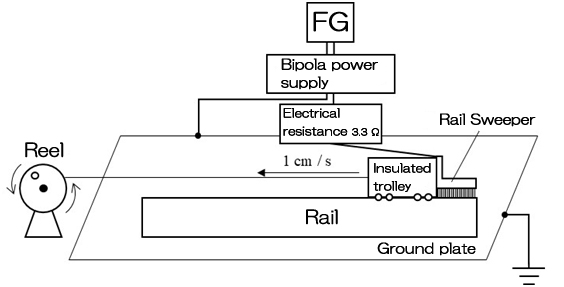

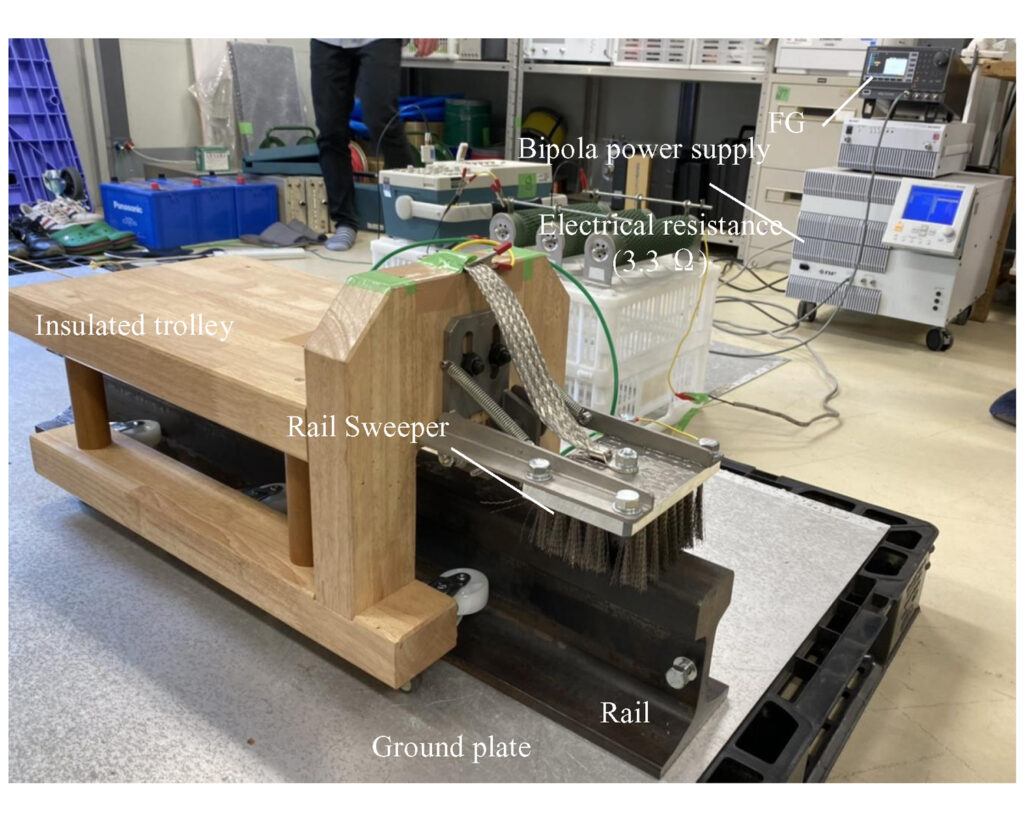

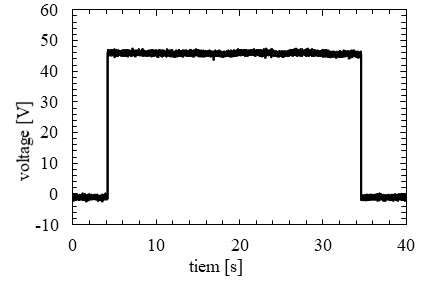

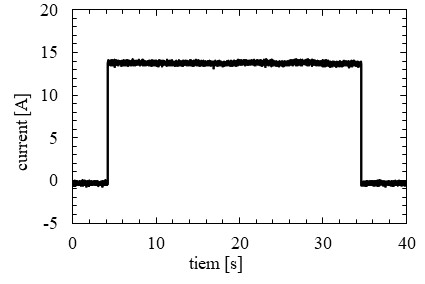

The input of voltage through a function generator was amplified to 50 V by a bipolar power supply. Then the 50 V was applied to 3.3 Ω (three 10 Ω resistors arranged in parallel) resistance and to the series circuit of the rail sweeper (with a grounding belt) to verify the electrical performance.

A current of approximately 15 A flowed at the time of conduction.

During the test, we fixed the rail sweeper on the Castel insulator and wound the Kevlar rope attached to the insulator by a reel, while moving the rail sweeper on the rail. The moving speed was 1 cm/sec., the conduction time was set as 30 seconds.

Test equipment, jigs, etc.

Test equipment, jigs, etc.

| Name | Manufacturer | Model No. | Specification |

| Function Generator | NF Corporation | WF1967 | Oscillation frequency: DC-200 MHz |

| Maximum output voltage:20 Vp-p/open 10 Vp-p/50 | |||

| Bipolar Power Supply | NF Corporation | BP4620 | Oscillation frequency DE-150 kHz |

| Maximum voltage: ±60 V, maximum current: ±20 A (load resistance: 3 Ω) | |||

| Oscilloscope | Tektronix | TDS 3054C | Bandwidth: DC-500 MHz |

| Passive Probe | Tektronix | P6139A | Bandwidth: DC-500 MHz, input voltage: 300 V |

| Resistance: 10 Ω, power rating: 1000 W (using three units in parallel) | |||

| Ceramic core resistor | TE Connectivity | TE 1000B 10RJ | Resistance: 10 Ω, power rating: 1000 W (using three units in parallel) |

Layout Overview

Test Device

Test result

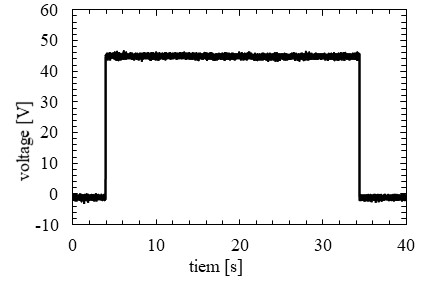

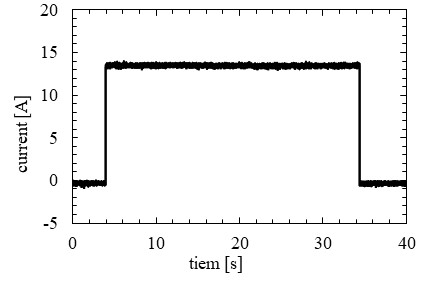

1.Voltage application to Rail Sweeper (with grounding belt) in stop state (46V, 3.3Ω, 14A, 30Sec)

2.Voltage application to Rail Sweeper (with grounding belt) in move state (46V, 3.3Ω, 14A, 30Sec)

Discussion

(Quoted from the report of Professor Kazuo Yamamoto of Electrical and Electronic Engineering, Faculty of Engineering, Chubu University.

Using a function generator and a bipolar power supply, we confirmed the electric conduct between the brush section and the rail by applying approximately 50 V Voltage to the Rail Sweeper (with a grounding belt) for 30 seconds. As the result, we confirmed the conduct of 15 A current.

Also, we confirmed that there was no performance degradation on the brush part even after a long time (the 30s) apply of approximately 15A.

From the previous test using an actual crane, we found out the largest current in the 200V ground fault system was approximately 20A. The test was conducted under the condition of resistance between the brush and rail is getting stronger as oxide film was formed on the rail used for this test. We successfully confirmed the conduct without any problem under these conditions.