Strength of wax-base solid lubricant

Tokki has two kinds of wax-base solid lubricant. One is solid lubricant solidified with soft natural hardening type oil such as paraffin, and the other one is the mixture of solid lubricant and clay, fired at 800℃.

The former solid lubricant with the texture that resembles crayons and candles is applied on the target to form wax film just like coloring paper with crayons. Also, the latter with the texture that feels similar to graphite and lead of pencils is applied on the target to form wax film just like coloring using graphite or the lead of pencils.

Naturally, the mechanical strength of each lubricant varies significantly. The strength of Bordon wax and Supper Wax, solid lubricant solidified with soft natural hardening type oil such as paraffin, may range drastically depending on ambient temperature.

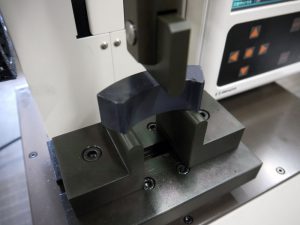

We introduced a tensile and compression testing machine complying with a request one of our customers to be provided with specific strength value.

Here, we provide the rupture value of the wax measured through a three-point bending test and the rupture condition measured through the reciprocation test.

Three-point bending test

The three-point bending test is one of the test methods to measure bending strength and deformation of materials. A sample in the shape of a round or square bar rests on support from both ends is subject to a concentrated load at its center to be examined how it deforms. The test may not be suitable for determining the basic characteristics of materials due to the unequal bending moment loaded to the material. However, it is suitable to measure the fracture mechanics of wax since the method is used in industrial tests to examine the bending workability of materials.

Test object piece

Bordon Wax (large), (small) Bordon High Temperature Wax (large), (small)

(Super Wax was excluded from the test because of encapsulated paste in it)

Test method

Using test pieces that had been kept in thermostat chambers set at -10℃, 0℃, 25℃, 40℃, 50℃, 60℃, 70℃, and 80℃ for an hour, three pieces for each temperature, we measured the breaking strength with the three-point bending test.

Test equipment

Tensile and compression testing machine STD-203NB (IMADA CO., LTD)

| Result of the three-point bending test (N), average of the three pieces | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| -10℃ | 0℃ | 25℃ | 40℃ | 50℃ | 60℃ | 70℃ | 80℃ | |||

| Bordon Wax (large) | 1779 | 1523 | 1309 | 1227 | 879 | 456 | 254 | 149 | ||

| Bordon Wax (small) | 922 | 777 | 699 | 662 | 515 | 229 | 131 | 87 | ||

| Bordon High Temperature Wax (large) | 2128 | 2112 | 2125 | 2085 | 2127 | 2122 | 2125 | 2041 | ||

| Bordon High Temperature Wax (small) | 1225 | 1274 | 1123 | 1127 | 1163 | 1040 | 1021 | 1025 | ||

Discussion

The strength of Bordon Wax declines as the temperature rises. The results of the test confirmed that the strength drops by nearly 50% when the temperature rises from 50℃ to 60℃.

This is because the solid lubricant is solidified with a soft natural hardening type oil. Therefore, our instruction manual for wax specifies the ambient temperature for Bordon Wax and Super Wax from -30℃ to 55℃ approximately.

Bordon High-Temperature Wax has demonstrated a minor change along with temperature differences, large and small alike.

This is because the mixture of solid lubricant and clay is fired at 800℃ to obtain the texture of terracotta. The instruction manual for the wax specifies the ambient temperature for Brdon High-Temperature Wax as approximately 250℃.

Solid lubricant starts oxidizing and losing its lubricating effect gradually at 350℃. The wax itself can be used when the temperature is lower than 350℃, however, springs or bearings for the applicator reach their serviceability limit state at approximately 250℃.

Reciprocation bending test

Lubricant film is formed on flange faces of the crane wheel when Bordon Wax, and our wax products, is pressed against them. Therefore, a lateral force is applied on the wax edge from the flange face with respect to the wheel rotation direction. As the crane repeats its forward and backward movements, the lateral force is applied irregularly on the wax edge for both plus and minus directions.

With the reciprocation bending test, we managed to determine the strength of wax by applying the heat and load similar to those in actual usage without any further compromise.

Test object piece

Bordon Wax (large), (small) Bordon High Temperature Wax (large), (small)

(Super Wax was excluded from the test because of encapsulated paste in it)

Test method

Direct application of hot air blasts of 50℃ and 60℃ to the wax from the hot air generator.

(temperature sensor is fixed on the side of the wax)

We reconstructed the condition where the wax is installed on the actual vehicle by creating a jig to mount directly to the wax holder of the flange applicator.

A load was placed on the sides of wax while holding it with a U-shaped jig where up and down movement takes place.

For one trial of 30 seconds, the pressure was increased until the wax reached the set value of 20N while the up-down movement was repeating itself. The test was terminated either when the wax was ruptured or the set of 100 trials were completed.

Test equipment

Tensile and compression testing machine STD-203NB (IMADA CO., LTD)

As an advance preparation, we conducted a test to see how many newtons it took to rupture the wax set in the wax holder at room temperatures. Since the wax ruptured at 59N, we decided to set the load at 20N, 1/3 of the rupture load. (When the room temperature raised to 60℃ during the three-point bending test, the strength decreased by 40% compared to the room temperature.)

| Reciprocation bending test (the value at which the wax ruptured while the jig moving up) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| normal temperature (34℃) | ||||||||||

| Bordon Wax (large) | 59N | |||||||||

| Bordon Wax (small) | 37N | |||||||||

| Bordon High Temperature Wax (large) | 82N | |||||||||

| Bordon High Temperature Wax (small) | 45N | |||||||||

Bordon (large) demonstrated an extremely low strength of 59N compared with the result of the three-point bending test (25℃, 1309N). It is mainly due to the development of a cantilever load on the wax and a sharp dent where the wax was held with a securing board (spring steel).

| The result of the reciprocation bending test(number of trials before the wax ruptured at 20N pressure) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 50℃ | 60℃ | |||||||||

| Bordon Wax (large) | 100trials | Rupture at 13th trial out of completed 100 trials of trial | ||||||||

| Bordon Wax (small) | 100trials | Rupture at 21th trial out of completed 100 trials of trial | ||||||||

| Bordon High Temperature Wax (large) | 100trials | 100trials | ||||||||

| Bordon High Temperature Wax (small) | 100trials | 100trials | ||||||||

Discussion

We confirmed that the wax ruptured under a small force of 20N due to the continuous loading in plus and minus directions when it was exposed to the high temperature of 60℃ and more.

With an actual crane, factors such as micro-vibration transmitted from the wheels to the wax and uneven friction resistance in acceleration and deceleration can cause damage to the wax, when the crane is partially or shortly exposed to the heat of more than 60℃.

We confirmed the mark of securing board, which is on the back of each wax, and no damage was caused even after 100 trials at 50℃ or at room temperature.

In the case of wax at 50℃, the edge of securing board was marked with a straight line whereas, in the case of wax at room temperature, there were two lines of marks. This is due to the concave developed on the center of the back of wax. At room temperature, the hardness of wax is maintained to leave two lines of marks. As the temperature increases, the lesser hardness to leave indentation deep enough to reach the concave. Thus, the borderline that holds the wax on the securing board must have acted as the pivot of friction resistance and become the starting point of the crack.

Conclusion

We recommend that you use

Bordon High Temperature Wax

when ambient temperature exceeds 55℃.

グリースから乗り換えなど固体潤滑剤&塗布装置のお問い合わせは0561-82-7225受付時間 9:00 - 18:00 [ 土日・祝日除く ]

お問い合わせはこちら お気軽にお問い合わせください。